| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Polywell

Model Number : PA66GF25

Place of Origin : China

Certification : SGS

MOQ : 500 KGS

Price : USD 1,500-1,900/T

Packaging Details : Nylon Bag

Delivery Time : 15-20 working days

Payment Terms : 50% T/T before production, 50% T/T before delivery

Supply Ability : 20 tons per month

Tensile Strength : ≥80 MPa

Density : 1.25-1.35 g/cm3

Abrasion Resistance : Good

Shore hardness : 80±5

Impact Strength : ≥35 KJ/m2

Temperature of deflection under load : ≥240℃

Melting Point : 240°C

Name : Polyamide Nylon 66

Usage : Construction material

Plastic Properties After Heated : Thermoplastic plastics

PA has the advantages of high mechanical strength, high softening point, good wear resistance, self-lubrication, cushioning, sound deadening, excellent oil and chemical corrosion resistance, and good electrical insulation. Because of these superior performance, PA composite have already replaced some metals being as structural materials.

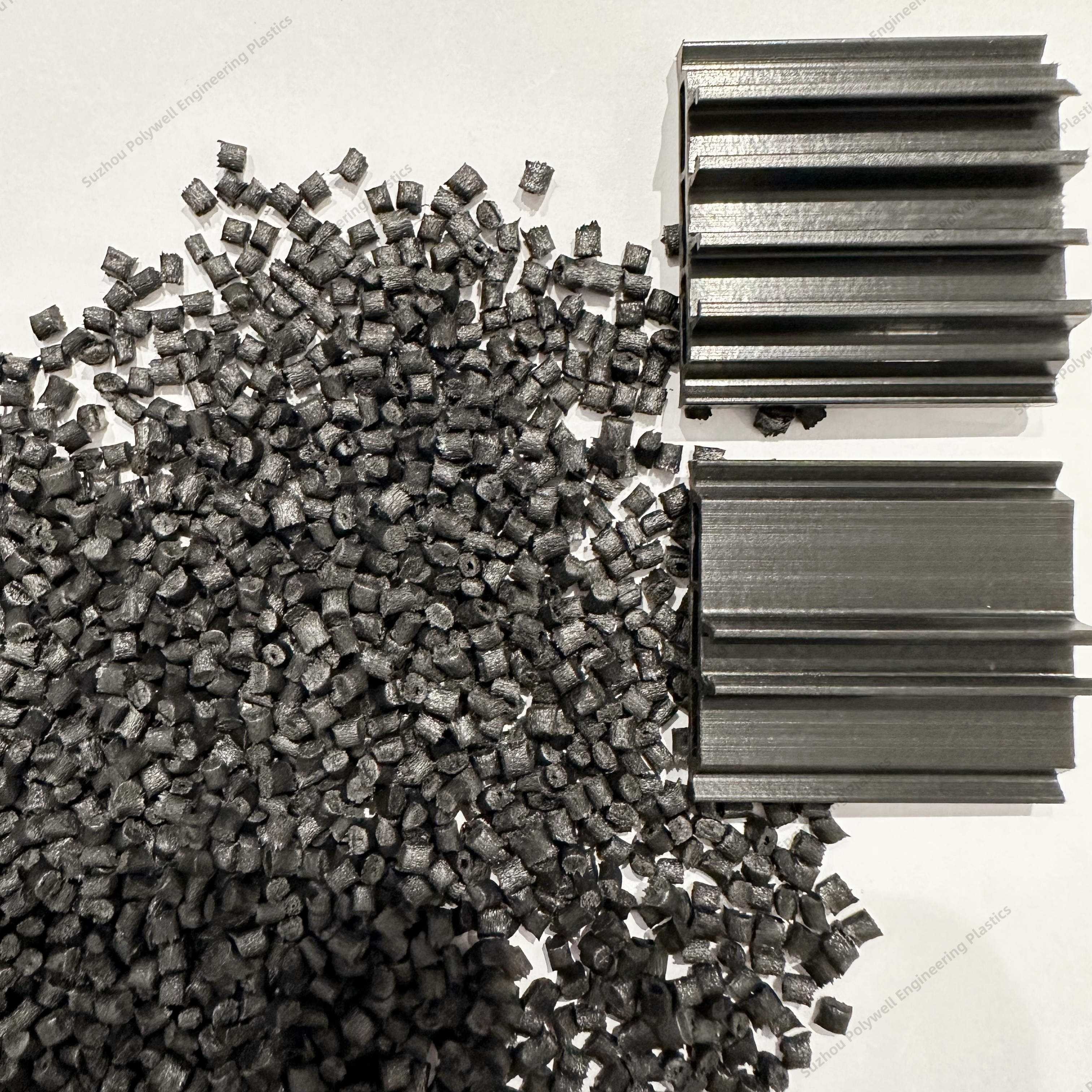

PA66GF25 Pellets is a type of glass fiber reinforced Plastic Granules which is made of Polyamide (PA), also known as Nylon 66.

This material provides excellent features such as outstanding Impact Strength of ≥35 KJ/m2, Density of 1.25-1.35 G/cm3, Tensile Strength of ≥80 MPa, and a Melting Point of 230-240°C. PA66GF25 Pellets is a viable option for a wide range of applications due to its superior strength and excellent mechanical properties. With a good performance in impact, fatigue, and wear resistance, PA66GF25 Pellets is an ideal choice for many industrial applications.

Polywell PA66 Granules Performance Table

| NO. | Item | Unit | GB/T 23615.1-2009 | PW-Technical specification |

| Material Properties | ||||

| 1 | Density | g/cm3 | 1.3±0.05 | 1.28-1.35 |

| 2 | Linear expansion coefficient | K-1 | (2.3-3.5)*10-5 | (2.3-3.5)*10-5 |

| 3 | Vicat softening temperature | ºC | ≥230 | ≥233 |

| 4 | Melting point | ºC | ≥240 | ≥240 |

| 5 | Testing for tensile cracks | - | No cracks | No cracks |

| 6 | Shore hardness | - | 80±5 | 80-85 |

| 7 | Impact strength(Unnotched) | KJ/m2 | ≥35 | ≥38 |

| 8 | Tensile strength(longitudinal) | MPa | ≥80a | ≥82a |

| 9 | Elasticity modulus | MPa | ≥4500 | ≥4550 |

| 10 | Elongation at break | % | ≥2.5 | ≥2.6 |

| 11 | Tensile strength(transverse) | MPa | ≥70a | ≥70a |

| 12 | High temperature tensile strength(transverse) | MPa | ≥45a | ≥47a |

| 13 | Low temperature tensile strength(transverse) | MPa | ≥80a | ≥81a |

| 14 | Water resistance tensile strength(transverse) | MPa | ≥35a | ≥35a |

| 15 | Aging resistance tensile strength(transverse) | MPa | ≥50a | ≥50a |

1. Sample water content less than 0.2% by weight.

2. Norm laboratory condition:(23±2)ºC and (50±10)% relative humidity.

3. The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

Specially used in thermal break strips, thermal bridge, heat insulation bar, etc.

Polyamide Nylon 66 provides technical support and services, such as:

Q: About Sample

A: Sample is Free, but the express fee is collect or you pay us the cost in advance.

Q: About MOQ

A: For the polyamide granules, MOQ is 500 kgs. For the thermal break strips, MOQ is 5,000 meters.

Q: About Customizing Special shape of polyamide Profiles and its period

A: You can customize the special shape of polyamide strips. If we didn't meet this shape before, we will make new mold for you, and you should pay for the mold.

Q: About Customizing Package Style and Marks

A: You can customize the package style and marks.

Q: Why your price is higher/lower than others?

A: For years specializing in polyamide granules and thermal break strips has bestowed us experienced and skilled technical workers and production workers. We promise the stability of products and the high-quality of raw material. Furthermore, we can provide technical support from raw material to the final appliance. Believe in that you can get better products and service with lower price.

Q: About warranty

A: We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately.

Q: About Payment or other question

A: 50% T/T deposit before production, 50% T/T balance before loading.

Suzhou Polywell Engineering Plastics Company is located in the city of Zhangjiagang, Jiangsu Province, China. Our company has devoted more than ten years to the research and development and production of nylon extruding profiles. According to customer reaction, using our PA66 granules for production can get high yiedl, easy start-up, and get less scrap in the early start-up stage. There will be no lack or incomplete of profiles in the production process, thus avoiding material waste.

Pleass feel free to contact us if you have any questions.

Name: Camille

E-mail: camille@szpolywell.cn

Tel: +86-13584481777

Address: Zhangjiagang City, Jiangsu Province, China

|

|

High Elasticity Modulus Polyamide Nylon 66 Chips with Melting Point of 240°C Images |